CHAPTER 3

Findings and Applications

This chapter discusses the results of the research performed. A portion of these results covering characterization, reactivity, and reactivity tests are detailed summaries of relevant content from seven studies led by the University of Miami (Y. Wang 2022; Y. Wang, Acarturk, et al. 2022; Y. Wang, Ramanathan, et al. 2022a; Y. Wang, Burris, et al. 2022; Y. Wang, Burris, et al. 2021; Y. Wang, Ramanathan, et al. 2022b; Y. Wang, Burris, et al. 2023).

Characterization Results

Some ashes were off-specification for various reasons under AASHTO M 295-21 (see Table 16). Some of the tested ashes, such as the CFB ash and bottom ash, are not covered under the current specification. Other off-specification limits of some of these ashes include the sulfate content (ash G, 17.4%), sum of oxides (ash G, 37.8%), fineness (ash L, 50.6% retained on the 45-µm sieve), water requirement (ash S, 110%), moisture content (ash T, 5.2%), LOI (ash U, 16.5%), and SAI (ash S). Two coarse ashes had greater than 10% retained on the 150-µm sieve (L and S), which is a new limit in ASTM C618-23e1. Several ashes were marginal for sum of oxides and LOI. Interestingly, most of the off-specification and marginal ashes were Class C. It is generally assumed that processed or beneficiated coal ashes (B, K, N, O, and R) are allowed in the AASHTO M 295 standard, although this is not explicitly stated.

The chemical properties of the coal ashes are classified in Table 17 as they relate to limits in AASHTO M 295-21; the physical properties of the ashes as they relate to limits in AASHTO M 295-21 are in Table 18. These coal ashes are discussed using the nomenclature in the “Paper Designation” column in Y. Wang, Acarturk, et al. (2022). XRF data in Table 17 showed a strong linear correlation between MgO and CaO contents, which did not change with storage or processing. Excluding one ash with very high SO3 content, there was also a moderate correlation between SO3 and CaO contents. This finding is well-known from literature but not for unconventional ashes. One implication of these correlations is the potential for durability concerns associated with SO3 and MgO contents to increase in Class C ashes, whether standard or not. With regard to composition, several unconventional ashes showed properties not seen in standard ashes—most commonly differences in SO3, sum of the oxides, and LOI.

The mineral phase contents for each ash are displayed in Tables 19, 20, and 21. XRD data showed all ashes were highly amorphous, with amorphous contents ranging from 40% to 93%, averaging 73%. Average values were significantly greater for Class F (81%) than Class C (57%). Class F ashes had mullite and quartz as major crystalline phases whereas Class C’s were quartz, C3A, and merwinite. The off-specification high-SO3 ash (17.4%) which was very fine (median particle size d50 = 4.1 µm) had unique crystalline phases including enstatite (13.6%), scawtite (8.1%), and bassanite (6.0%), among others.

Table 16. AASHTO M 291-21 compliance of coal ashes.

| Sample | AASHTO M 295-21 (Pass or Fail) | Specification Limit(s) Failed |

|---|---|---|

| Standard Ashes | ||

| A | Pass | 7-day SAI |

| D | Pass | None |

| E | Pass | None |

| F | Pass | 7-day SAI |

| H | Pass | None |

| I | Pass | None |

| P | Pass | None |

| Q | Pass | None |

| Unconventional Ashes | ||

| B | Pass | None (processed) |

| K | Pass | None (processed) |

| M | Fail | 7- and 28-day SAIs, harvested |

| N | Pass | None (processed) |

| O | Pass | None (processed) |

| R | Pass | None (processed) |

| S | Fail | 7-, 28-, and 56-day SAIs, WR, harvested |

| C | Fail | WR, CFB ash |

| G | Fail | ΣSiO2 + Al2O3 +Fe2O3, SO3 |

| J | Pass | None |

| L | Fail | 45 μm sieve retention, 7-day SAI |

| T | Fail | Moisture, harvested |

| U | Fail | LOI, 45 μm sieve retention, WR, harvested |

| V | Fail | Bottom ash blend |

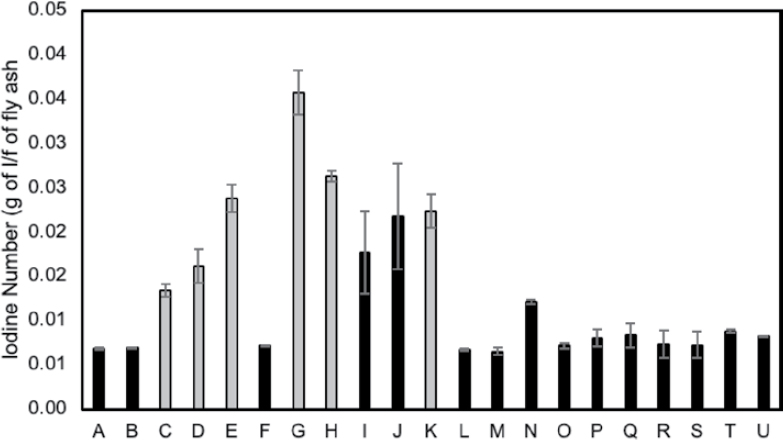

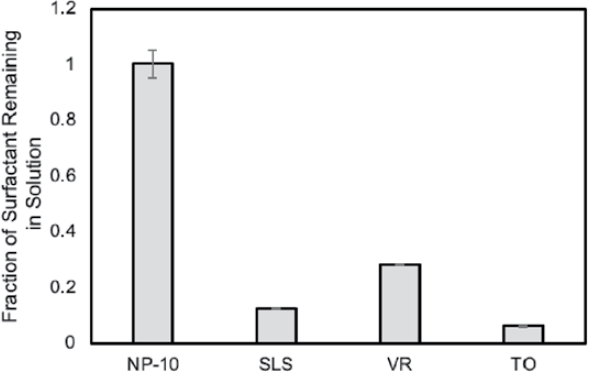

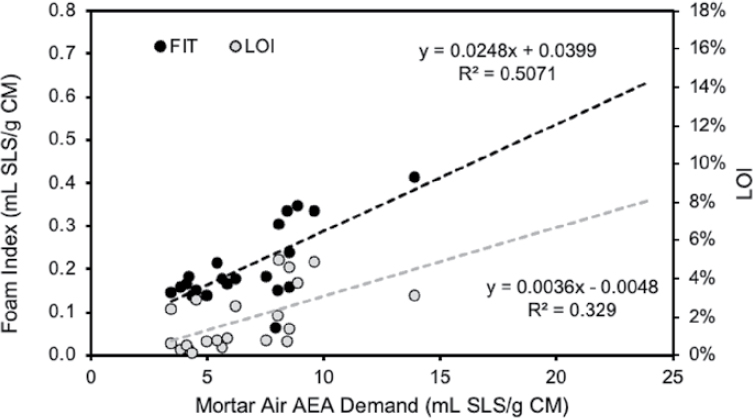

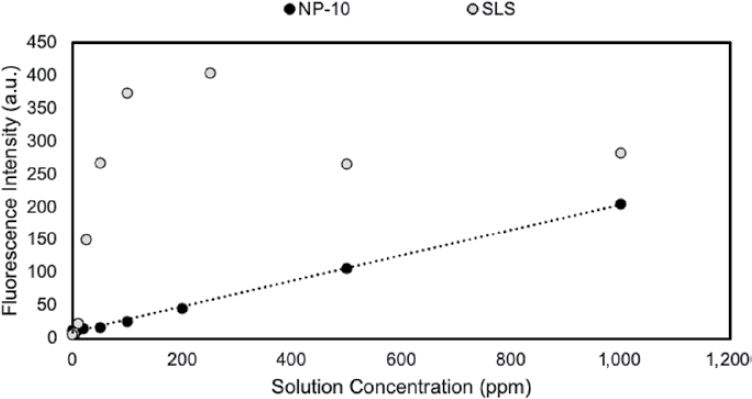

Moisture contents determined from TGA and/or oven were low for all ashes, with the maximum value < 1.0% and average 0.22%. LOI values were generally lower than 5% when determined using either method, with a few notable high-LOI unconventional ash exceptions. In general, LOI at 750°C and 950°C using furnace/TGA were correlated, suggesting temperature choice was not particularly important for trends (Figure 1). However, the correlation was not 1:1 and LOI values from the TGA at 950°C were two to three times higher than those at the lower temperature of 750°C. The correlation for the LOI from the furnace was closer to 1:1. Both temperature and test method affected LOI values because of the complex chemistry of coal ashes. In both cases, the carbonates decomposed and organic matter volatilized. When tested in nitrogen, unburnt carbon did not burn or oxidize, but could reduce iron oxides/sulfides and produce carbon dioxide or monoxide, leading to weight loss, which typically occurs beyond 700°C but is more obvious at 950°C. For such coal ashes, LOI using TGA at 950°C was much higher than the TGA value at 750°C. In air, the unburnt carbon could burn/oxidize to CO2, and sulfides, sulfur, and iron minerals could oxidize and gain weight, which reduced the LOI. For Class F ashes, the furnace LOI at 950°C increased with Fe2O3 content, but there was no such trend for Class C ashes, showing that iron content may be a contributor to LOI in Class F ashes at 950°C. LOI and LOI values from TGA were not correlated at either temperature. Due to the simplicity of the ignition tests, using LOI (with either test) as an indicator of AEA adsorption is misleading, because carbon is one of several substances responsible for LOI. However, the LOI using the furnace at 750°C is likely the “best” test, given issues with atmosphere and higher-temperature testing (Y. Wang, Burris, et al. 2022).

Particle size was similar for most of the coal ashes used in this testing. Only a select number of coal ashes had significantly different particle size distributions. Particle size distributions for the Class F ashes are shown in Figure 2 and for the Class C ashes in Figure 3. Ash J (the cyclone collector ash) and K (the Class C surfactant-modified ash) were significantly finer than the majority of coal ashes. S, a reclaimed coal ash and L, specifically chosen for its high coarseness, were significantly coarser than the other ashes. Fineness, determined using ASTM C430 methods, the Blaine fineness, and the d50 of the ashes, is shown in Table 18. These data show that at least some of the unconventional fly ashes (L and S) have unusual fineness.

Table 17. Chemical properties of the coal ashes.

| Samples | Paper Designation | Beneficiated | Class | Supplier Notes | SiO2 + Al2O3 + Fe2O3 (%) | CaO (%) | SO3 (%) | Moisture Content (%) | LOI (%) | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | MgO (%) | K2O (%) | Na2O (%) | Na2Oeq (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50% min | ≤ 18, F > 18, C | 5% max | 3% max | 5% max | N/A | N/A | N/A | N/A | N/A | N/A | 4.5% max – R80, Class F ashes | |||||

| Standard Ashes | ||||||||||||||||

| A | F1 | N | F | Class F, in-spec | 83.4 | 5.4 | 0.41 | 0.23 | 0.64 | 55.6 | 17.4 | 10.4 | 1.4 | 2.6 | 1.2 | 2.87 |

| D | C2 | N | C | Class C, in-spec | 63.5 | 19.9 | 0.80 | 0.30 | 0.69 | 40.4 | 18.6 | 4.6 | 3.7 | 0.6 | 1.4 | 1.8 |

| E | C3 | N | C | Class C with high SO3 and marginal oxides | 50.1 | 25.3 | 2.75 | 0.18 | 0.79 | 31.2 | 15.2 | 3.6 | 7.5 | 0.3 | 1.7 | 1.94 |

| F | F3 | N | F | Class F with high LOI | 82.3 | 3.7 | 0.54 | 0.11 | 4.88 | 47.2 | 19.0 | 16.1 | 0.9 | 2.5 | 0.9 | 2.51 |

| H | C5 | N | C | Class C with marginal oxides | 50.9 | 24.8 | 2.18 | 0.45 | 1.43 | 31.4 | 14.6 | 5.0 | 6.9 | 0.3 | 1.9 | 2.13 |

| I | F4 | N | F | Class F, in-spec | 71.1 | 11.9 | 0.58 | 0.11 | 0.34 | 52.0 | 14.0 | 5.0 | 4.3 | 2.1 | 3.6 | 5.02 |

| P | F10 | N | F | Class F, in-spec | 88.7 | 1.7 | 0.10 | 0.23 | 3.83 | 51.6 | 25.9 | 11.2 | 1.0 | 2.3 | 0.4 | 1.89 |

| Q | F11 | N | F | Class F with high LOI | 82.2 | 5.0 | 0.65 | 0.18 | 4.62 | 41.9 | 20.1 | 20.2 | 0.7 | 1.5 | 0.7 | 1.71 |

| Unconventional Ashes | ||||||||||||||||

| B | F2* | Y | F | Off-spec ash, beneficiated by sieving/grinding | 84.0 | 4.3 | 0.08 | 0.17 | 0.43 | 60.7 | 20.9 | 2.4 | 0.8 | 2.2 | 4.3 | 5.75 |

| K | C6* | Y | C | Surfactant beneficiated ash with marginal oxides | 51.2 | 24.8 | 2.05 | 0.15 | 0.95 | 31.3 | 16.2 | 3.7 | 7.2 | 0.3 | 1.6 | 1.85 |

| M | F7* | Y | F | Reclaimed ash, dried and sieved, off-spec fineness | 83.3 | 2.1 | 0.21 | 0.30 | 2.90 | 46.7 | 24.4 | 12.3 | 0.9 | 2.4 | 0.2 | 1.76 |

| N | F8-BL^* | Y | F | Blend of Class C and Class F ashes | 69.2 | 14.5 | 0.69 | 0.14 | 0.79 | 43.8 | 20.0 | 5.5 | 3.5 | 1 | 1.3 | 1.95 |

| O | F9* | Y | F | LOI electrostatic beneficiated ash | 82.4 | 4.7 | 1.27 | 0.77 | 2.57 | 48.8 | 18.8 | 14.8 | 0.9 | 2.3 | 0.7 | 2.23 |

| R | F12* | Y | F | Beneficiated ash by HT, high fineness | 90.5 | 2.2 | 0.11 | 0.10 | 0.70 | 52.2 | 29.1 | 9.2 | 1.0 | 2.6 | 0.4 | 2.05 |

| S | F13* | Y | F | Reclaimed ash, beneficiated by HT, extreme coarseness | 92.0 | 1.5 | 0.11 | 0.10 | 0.30 | 54.8 | 27.6 | 9.6 | 0.9 | 2.4 | 0.3 | 1.85 |

| C | C1-CFB^ | N | C | CFB ash | 65.7 | 18.5 | 4.11 | 0.22 | 0.69 | 46.1 | 16.6 | 3.0 | 2.4 | 1.1 | 0.3 | 1.00 |

| G | C4 | N | C | Off-spec ash, off-spec SO3 | 37.8 | 25.5 | 17.45 | 1.05 | 2.08 | 26.6 | 7.8 | 3.4 | 3.9 | 0.8 | 3.4 | 3.94 |

| J | F5-CCA^ | N | F | Cyclone collector ash | 61.5 | 15.3 | 2.28 | 0.28 | 3.10 | 34.1 | 16.8 | 10.6 | 3.8 | 1.5 | 1.9 | 2.92 |

| L | F6 | N | F | Off-spec, low fineness, extreme coarseness | 86.4 | 3.9 | 0.10 | 0.09 | 0.22 | 63.7 | 19.9 | 2.8 | 0.7 | 2.2 | 3.9 | 5.29 |

| T | F14 | N | F | Harvested impounded ash, off-spec moisture content | 90.8 | 2.4 | 1.01 | 5.19 | 5.00 | 47.9 | 22.7 | 15.3 | 0.8 | 2.1 | 0.9 | 2.39 |

| U | F15 | N | F | High-LOI ponded ash blend | 73.7 | 1.9 | 0.56 | ----- | 16.46 | 41.9 | 18.5 | 13.3 | 0.6 | 1.7 | 1.1 | 2.22 |

| V | F16* | Y | F | Bottom ash blend | 84.6 | 6.1 | 0.21 | 0.20 | 2.43 | 60.9 | 18.7 | 4.9 | 1.0 | 1.4 | 2.1 | 2.05 |

Note: sum of the primary oxide contents = (SiO2+Al2O3+Fe2O3)

HT = high-temperature treatment

* = beneficiated

^ = not covered in the specification

bold = off-specification properties

bold italic = marginal properties

Table 18. Physical properties of the coal ashes.

| Samples | Paper Designation | Beneficiated | Class | Supplier Notes | Fineness 45 μm % retained (sieved) | Fineness 45 μm % retained (PSD) | Fineness 150 μm % retained (sieved) | 7-day SAI (%) | 28-day SAI (%) | 56-day SAI** (%) | Water Req. (%) | SG (kg/m3) | SSA (laser) (m2/kg) | Blaine Fineness (m2/kg) | d50 (mm) N/A |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 34, max | 34, max | N/A | 75, min | 75, min | 75, min | 105, max | N/A | N/A | N/A | N/A | |||||

| Standard Ashes | |||||||||||||||

| A | F1 | N | F | Class F, in-spec | 24.4 | 29.4 | 1.0 | 68 | 77 | 78 | 92 | 2.37 | 513 | 240.6 | 20.4 |

| D | C2 | N | C | Class C, in-spec | 15.0 | 24.6 | 1.0 | 82 | 87 | 94 | 100 | 2.59 | 685 | 402.1 | 16.6 |

| E | C3 | N | C | Class C with high SO3 and marginal oxides | 8.9 | 14.3 | 0.5 | 124 | 91 | 112 | 94 | 2.78 | 833 | 413.4 | 9.8 |

| F | F3 | N | F | Class F with high LOI | 21.7 | 24.0 | 4.1 | 72 | 82 | 95 | 91 | 2.45 | 457 | 227.7 | 18.3 |

| H | C5 | N | C | Class C with marginal oxides | 12.4 | 20.6 | 1.5 | 81 | 100 | 101 | 94 | 2.84 | 753 | 405.1 | 12.7 |

| I | F4 | N | F | Class F, in-spec | 21.4 | 36.0 | 2.1 | 100 | 98 | 99 | 88 | 2.55 | 491 | 291.4 | 24.6 |

| P | F10 | N | F | Class F, in-spec | NM | 20.2 | 2.4 | 86 | 96 | 110 | 100 | 2.57 | 544 | 299.6 | 14.3 |

| Q | F11 | N | F | Class F with high LOI | NM | 30.3 | 1.1 | 79 | 84 | 92 | 104 | 2.38 | 445 | 221.2 | 23.2 |

| Unconventional Ashes | |||||||||||||||

| B | F2* | Y | F | Off-spec ash, beneficiated by sieving/grinding | 22.7 | 31.5 | 1.2 | 77 | 86 | 91 | 100 | 1.89 | 374 | 215.4 | 25.7 |

| K | C6* | Y | C | Surfactant beneficiated ash with marginal oxides | 11.9 | 21.9 | 1.1 | 100 | 96 | 98 | 88 | 2.84 | 764 | 422.6 | 12.5 |

| M | F7* | Y | F | Reclaimed ash, dried and sieved, off-spec fineness | 27.6 | 36.2 | 5.5 | 71 | 69 | 78 | 94 | 2.43 | 473 | 345.9 | 24.9 |

| N | F8-BL^* | Y | F | Blend of Class C and Class F ashes | 27.6 | 30.7 | 2.5 | 79 | 102 | 99 | 94 | 2.52 | 575 | 345.6 | 20.5 |

| O | F9* | Y | F | LOI electrostatic beneficiated ash | 19.0 | 24.1 | 1.4 | 79 | 89 | 96 | 100 | 2.43 | 551 | 291.0 | 16.4 |

| R | F12* | Y | F | Beneficiated ash by HT, high fineness | 12.4 | 12.8 | 0.4 | 82 | 95 | 97 | 102 | 2.49 | - | 290.1 | 13.3 |

| S | F13* | Y | F | Reclaimed ash, beneficiated by HT, extreme coarseness | 22.1 | 60.4 | 12.1 | 68 | 62 | 69 | 110 | 2.38 | 249 | 149.0 | 62.6 |

| C | C1-CFB^ | N | C | CFB ash | 31.1 | 31.6 | 1.0 | 78 | 86 | 89 | 107 | 2.59 | 538 | 320.2 | 22.4x |

| G | C4 | N | C | Off-spec ash, off-spec SO3 | 15.9 | 15.5 | 0.6 | 79 | 85 | 97 | 94 | 2.55 | 1590 | 306.0 | 4.1 |

| J | F5-CCA^ | N | F | Cyclone collector ash | 10.6 | 15.8 | 4.2 | 106 | 87 | 108 | 94 | 2.79 | 789 | 454.6 | 9.9 |

| L | F6 | N | F | Off-spec, low fineness, extreme coarseness | 50.6 | 63.1 | 14.6 | 70 | 79 | 80 | 100 | 1.76 | 115 | 152.4 | 66.2 |

| T | F14 | N | F | Harvested impounded ash, off-spec moisture content | NM | 31.2 | 6.0 | 77 | 92 | 89 | 100 | 2.56 | - | 214.9 | 23.1 |

| U | F15 | N | F | High-LOI ponded ash blend | NM | 34.9 | 6.7 | 75 | 89 | 93 | 106 | 2.42 | - | 264.9 | 24.9 |

| V | F16* | Y | F | Bottom ash blend | 14.0 | 16.8 | 0.3 | 84 | 97 | 96 | 102 | 2.38 | - | 370.4 | 16.1 |

Note: HT = high-temperature treatment

* = beneficiated

** = not measured, determined via regression

^ = not covered in the specification

bold = off-specification properties

bold italic = marginal properties

45 μm retained = retention on U.S. standard sieve no. 325

150 μm retained = Retention on U.S. standard sieve no. 100

(laser) = attained via laser diffraction

NM = not measured

x = not accurate due to dispersion issues related to agglomerated but highly porous spongy particle

Table 19. Phase composition (%) of the Class F coal ashes determined using the Rietveld method.

| Sample | Class | Suppliers’ Notes | Amorphous | Hematite (Fe2O3) | Mullite (Al4+8Si2-8O10-6) | Magnetite (Fe3O4) | Maghemite ((Fe3+0.67-0.33)Fe3+2O4) | Merwinite (Ca3Mg(SiO4)2) | Magnesium Oxide (MgO) | Quartz (SiO2) | Anhydrite (CaSO4) | Free Calcium (CaO) | Calcite (CaCO3) | Monalbite (NaAlSi3O8) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Ashes | ||||||||||||||

| A | F | Class F, in-spec | 85.3 | 1.1 | 1.7 | 1.8 | 0.0 | 0.0 | 0.0 | 6.8 | 0.9 | 0.0 | 2.3 | 0.0 |

| F | F | Class F with high LOI | 79.7 | 3.0 | 6.2 | 0.0 | 3.4 | 0.0 | 0.0 | 5.9 | 1.3 | 0.5 | 0.0 | 0.0 |

| I | F | Class F, in-spec, off-spec fineness | 92.2 | 0.4 | 0.1 | 0.0 | 0.3 | 2.0 | 1.2 | 3.5 | 0.3 | 0.1 | 0.0 | 0.0 |

| P | F | Class F, in-spec | 70.9 | 1.4 | 16.5 | 0.7 | 1.3 | 0.0 | 0.0 | 8.0 | 0.7 | 0.3 | 0.0 | 0.0 |

| Q | F | Class F with high LOI | 72.9 | 2.3 | 9.4 | 2.0 | 2.7 | 0.2 | 0.4 | 7.0 | 2.2 | 0.4 | 0.0 | 0.0 |

| Unconventional Ashes | ||||||||||||||

| B | F | Off-spec ash, beneficiated by sieving/grinding | 88.7 | 0.3 | 5.5 | 0.2 | 0.8 | 0.1 | 0.0 | 2.5 | 0.5 | 0.1 | 0.0 | 1.3 |

| J | F | Cyclone collector ash | 92.7 | 0.8 | 0.0 | 1.8 | 0.0 | 0.0 | 0.0 | 0.4 | 4.4 | 0.0 | 0.0 | 0.0 |

| L | F | Off-spec, low fineness, extreme coarseness | 86.8 | 0.5 | 6.2 | 0.0 | 0.8 | 0.0 | 0.0 | 3.3 | 0.4 | 0.0 | 0.0 | 2.0 |

| M | F | Reclaimed ash, dried and sieved, off-spec fineness | 80.9 | 1.5 | 10.6 | 1.0 | 1.1 | 0.0 | 0.0 | 4.2 | 0.7 | 0.0 | 0.0 | 0.0 |

| N | F | Blend of Class C and Class F ashes | 82.7 | 0.9 | 3.0 | 0.5 | 0.0 | 4.7 | 1.2 | 6.5 | 0.6 | 0.0 | 0.0 | 0.0 |

| O | F | LOI electrostatic beneficiated ash | 80.4 | 1.7 | 5.3 | 2.2 | 1.8 | 0.0 | 0.0 | 6.9 | 1.2 | 0.2 | 0.0 | 0.0 |

| R | F | Beneficiated ash by HT, high fineness | 70.0 | 2.9 | 16.9 | 0.0 | 0.7 | 0.0 | 0.0 | 9.0 | 0.1 | 0.4 | 0.0 | 0.0 |

| S | F | Reclaimed ash, beneficiated by HT, extreme coarseness | 73.1 | 2.3 | 17.3 | 0.0 | 0.5 | 0.0 | 0.1 | 6.0 | 0.4 | 0.4 | 0.0 | 0.0 |

| T | F | Harvested impounded ash, off-spec moisture content | 76.2 | 2.6 | 9.8 | 0.0 | 3.4 | 0.0 | 0.0 | 7.7 | 0.2 | 0.1 | 0.0 | 0.0 |

| U | F | High LOI ponded ash blend | 68.9 | 4.0 | 12.7 | 3.5 | 0.0 | 0.0 | 0.0 | 10.1 | 0.4 | 0.5 | 0.0 | 0.0 |

| V | F | Bottom ash blend | 78.0 | 0.0 | 3.1 | 0.5 | 0.0 | 0.0 | 0.0 | 16.8 | 0.3 | 0.0 | 0.0 | 0.0 |

Note: Determination of phase content by the Rietveld method is typically not accurate to more than 1%, but phase compositions are shown to 0.1% as an indication of the presence of particular minerals in the sample and to provide a relative indication of the overall quantity present.

Table 20. Phase composition (%) of the Class C coal ashes determined using the Rietveld method.

| Sample | Class | Suppliers’ Notes | Amorphous | Hematite (Fe2O3) | Mullite (Al4+8Si2-8O10-6) | Magnetite (Fe3O4) | Maghemite ((Fe3+0.67-0.33)Fe3+2O4) | Merwinite (Ca3Mg(SiO4)2) | Magnesium Oxide (MgO) | Quartz (SiO2) | Cubic Tricalcium Aluminate ((CaO)3Al2O3) | Belite (Ca2SiO2) | Ye'elimite (Ca4Al6O12SO4) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Ashes | |||||||||||||

| D | C | Class C, in-spec | 77.8 | 0.3 | 2.1 | 0.5 | 0.0 | 3.8 | 1.2 | 5.5 | 5.4 | 0.0 | 0.0 |

| E | C | Class C with high SO3 and marginal oxides | 55.6 | 0.3 | 0.7 | 0.0 | 0.0 | 4.6 | 6.1 | 6.2 | 9.2 | 5.0 | 1.9 |

| H | C | Class C with marginal oxides | 60.0 | 0.5 | 2.3 | 0.0 | 0.0 | 6.0 | 5.5 | 5.9 | 10.0 | 6.4 | 0.0 |

| Unconventional Ashes | |||||||||||||

| C | C | CFB ash | 39.8 | 0.0 | 0.5 | 0.0 | 0.7 | 1.5 | 1.0 | 21.4 | 3.9 | 6.4 | 0.0 |

| G | C | Off-spec ash, off-spec SO3 | 42.6 | 0.0 | 3.3 | 0.0 | 0.0 | 3.7 | 0.0 | 1.0 | 2.4 | 4.2 | 0.0 |

| K | C | Surfactant beneficiated ash with marginal oxides | 65.0 | 0.5 | 0.0 | 0.0 | 0.0 | 3.1 | 5.1 | 4.6 | 7.6 | 4.3 | 0.9 |

Table 21. Phase composition (%) of the Class C coal ashes determined using the Rietveld method.

| Sample | Class | Suppliers’ Notes | Anhydrite (CaSO4) | Bassanite (Ca(SO4)·0.5H22O) | Gypsum (CaSO4·2H2O) | Free Calcium (CaO) | Portlandite (Ca(OH)2) | Calcite (CaCO3) | Gehlenite (Ca2Al(Al,Si)O7) | Monalbite (NaAlSi3O8) | Enstatite (MgSiO3) | Ammonium Iron Fluoride ((NH4)3FeF6) | Ammonium Dihydrogen Phosphate (NH4H2PO) | Scawtite (Ca7Si6(CO3)O18·2(H2O)) | Arcanite (K2SO4) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Ashes | |||||||||||||||

| D | C | Class C, in-spec | 1.0 | 0.0 | 0.0 | 0.3 | 0.0 | 0.8 | 1.4 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| E | C | Class C with high SO3 and marginal oxides | 3.1 | 0.0 | 0.0 | 2.8 | 0.0 | 2.9 | 1.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| H | C | Class C with marginal oxides | 2.0 | 0.0 | 0.0 | 1.6 | 0.0 | 1.8 | 3.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Unconventional Ashes | |||||||||||||||

| C | C | CFB ash | 10.1 | 0.0 | 0.0 | 3.9 | 0.0 | 5.4 | 5.6 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| G | C | Off-spec ash, off-spec SO3 | 0.0 | 6.0 | 1.4 | 0.0 | 2.2 | 1.9 | 1.7 | 0.0 | 13.6 | 4.8 | 2.0 | 8.1 | 1.1 |

| K | C | Surfactant beneficiated ash with marginal oxides | 2.0 | 0.0 | 0.0 | 2.2 | 0.0 | 1.5 | 3.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

Figure 2. Particle size distribution of the Class F ashes.

Figure 3. Particle size distribution of the Class C ashes.

In ASTM C618-23e1, a new maximum limit of 10% retained on the 150-µm sieve was introduced for harvested or coal ash containing bottom ash. This limit has not yet been added to AASHTO M 295. For this set of coal ashes, two coarse ashes had greater than 10% retained on the 150-µm sieve (L and S). However, whether coal ash L is harvested or contains bottom ash is unclear as this information was not provided by the supplier. There has been debate about the limit value at ASTM, with 5% being suggested instead of 10%. If the limit were set at 5%, five ashes (S, L, M, T, and U) would not pass. Four of these ashes did not pass other AASHTO M 295 specification limits, including for fineness (45-µm sieve), moisture content, LOI, and SAI. However, coal ash M would pass, and this ash performed well in concrete. From this dataset, it appears that the 5% limit may be overly restrictive for some coal ashes like M, and the 10% limit is more appropriate.

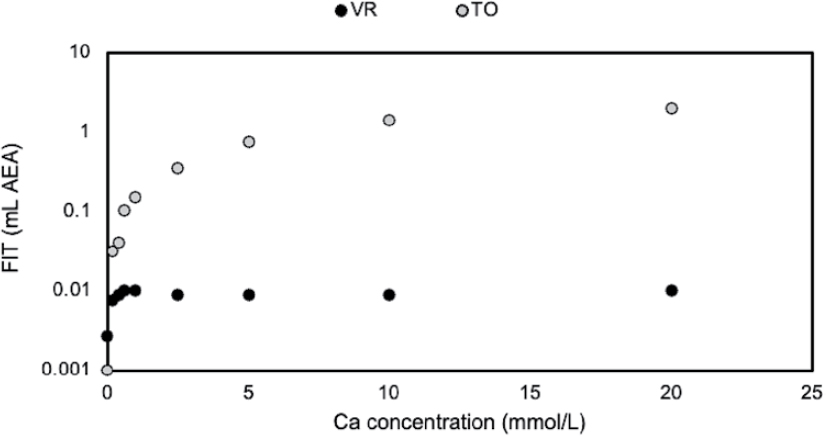

Coal ash particle morphology was typically complex and variable (see Figure 4). Some unconventional ashes showed a greater number of fractured particles due to beneficiation using grinding (Figure 4b). Irregular, larger particles were seen in some ashes (Figure 4d). Notably, particles in the CFB ash were irregular, angular, and highly porous, and very different from standard ashes (Figure 4c). Some ashes showed the presence of larger irregular-shaped particles, presumed to be carbon (Figure 4d), and there were trapped fly ash particles in some cases. As expected, the fly ashes off-specification for fineness showed a number of larger particles, both regular and irregular. Unusual morphologies were common in the unconventional ashes due to storage, weather, beneficiation, or to a different type of source.

Most coal ashes were composed of particles with a d50 between 10 and 25 µm. However, there were two very coarse ashes with 66.2 µm and 62.6 µm d50, and one very fine ash with 4.1 µm d50. The two coarsest ashes were off-specification for fineness (L and S). There was a strong nonlinear relationship between SSA and d50 values determined from laser diffraction (see Figure 5). There was a strong positive linear relationship between the 45-µm sieve retained amount and the d50 (see Figure 5); likewise between the Blaine fineness and laser diffraction SSA (see Figure 6). The laser diffraction SSA values were almost double the values from the Blaine test. While there were a few outliers, the strong correlations between the three measures show that one measurement is adequate and could be used to estimate the others for all coal ashes in most cases. The 45-µm retained value from sieving and laser diffraction were strongly correlated when coal ash S was removed

Figure 4. SEM morphologies of particles from four different coal ashes.

(Figure 7). Coal ash S showed a 40% difference in the 45-µm retained value between the sieve and the laser diffraction. All other test methods show coal ash S to be very coarse, which suggests the 45-µm retained value from sieving is inaccurate. For all other materials, on average, the difference between the two tests was 6%; the value from laser diffraction was in almost all cases higher, and the correlation was not 1:1. It is unclear why this is, but it could be related to particle morphology, test assumptions regarding particle shape, or test errors.

A comparison of the amorphous content in the standard and unconventional ashes is shown in Figure 8. Average coal ash amorphous content for the sample set was similar between the standard and unconventional coal ashes—averaging 75.3% and 78.2%, respectively. However, several of the unconventional ashes had very small amorphous contents; ashes C and G, the CFB and high-sulfate ashes, had amorphous contents of 39.8% and 42.6%, respectively. The lower amorphous contents in these ashes were accompanied by high levels of quartz and anhydrite in the CFB ash and high levels of enstatite (MgSiO3), bassanite [Ca(SO4)-0.5H2O], scawtite [Ca7Si6(CO3)O18·2(H2O)], and several other crystalline phases in ash G. Ashes E and H also had lower than normal amorphous content

Figure 8. Comparison of amorphous content in the standard and unconventional ashes.

(55.6 and 60.0%, respectively). Both standard Class C ashes had lower amorphous content due to the presence of high quartz, tricalcium aluminate (C3A), and belite (C2S) contents.

Overall, it does not seem that unconventional ashes are significantly different from standard sources of coal ash in terms of crystalline phase composition or amorphous content other than the two outliers. Additionally, amorphous content cannot be used as a definitive determinant of ash performance as several of these ashes with low amorphous content yielded high measures of reactivity in subsequent reactivity testing (see Table 22), and all exceeded the SAI limits shown in the Mortar Testing Results section.

Table 22. Results of R3 (7-day) and MR3 (10-day) reactivity tests.

| Samples | R3 | MR3 | ||

|---|---|---|---|---|

| Heat (J/g SCM) | Bound Water (g/100 g SCM) | Heat (J/g SCM) | Bound Water (g/100 g SCM) | |

| Standard Ashes | ||||

| A | 203.0 | 6.7 | 304.8 | 19.0 |

| D | 358.4 | 15.6 | 319.3 | 25.1 |

| E | 412.7 | 15.6 | 277 | 25.2 |

| F | 188.3 | 6.3 | 291.7 | 19.6 |

| H | 369.5 | 15 | 254.8 | 23.0 |

| I | 258.4 | 9.5 | 272.2 | 19.0 |

| P | 215.5 | 7.7 | 316.1 | 18.9 |

| Q | 157.0 | 6.2 | 287.6 | 18.5 |

| Unconventional Ashes | ||||

| B | 255.4 | 8.8 | 306.5 | 20.0 |

| K | 372.0 | 16.9 | 309.7 | 21.9 |

| M | 242.7 | 9.4 | 337.4 | 20.5 |

| N | 361.9 | 14.4 | 349.3 | 20.3 |

| O | 167.1 | 6.6 | 302.4 | 18.2 |

| R | 152.0 | 5.4 | 258.8 | 15.7 |

| S | 75.0 | 4.0 | 205.0 | 13.5 |

| C | 420.2 | 13.9 | 316.4 | 22.2 |

| G | 221.8 | 7.8 | 239.4 | 15.4 |

| J | 345.6 | 12.1 | 347.7 | 25.3 |

| L | 182.2 | 7.6 | 246.3 | 16.8 |

| T | - | 6.2 | 329.7 | 18.7 |

| U | - | 5.6 | 297.1 | 18.4 |

| V | - | 6.8 | 341.9 | 20.2 |

While some unconventional coal ashes displayed unusual properties, including excessive SO3 content, large 45-µm sieve retention, high LOI, and angular porous morphology, many unconventional ashes among those studied did not show properties substantially different from standard ones, suggesting that their use in concrete should be strongly considered. However, other results on pastes, mortar, and concrete are needed to confirm the suitability of these ashes for concrete.

Characterization findings:

- Unconventional ashes for the most part showed similar physicochemical properties to standard ashes when beneficiated, though some showed outlier properties.

- Outlier properties for unconventional ashes included increased particle size, high LOI, and high SO3.

- LOI determined from TGA or furnace depends on a number of factors, including temperature and test method, and is influenced by the complex chemistry of oxidation and reduction of carbon, sulfur, and iron. It is not simply a measure of carbon.

- Quantitative x-ray diffraction (QXRD) characterization showed generally similar amorphous or glassy phases between unconventional and standard ashes despite varied elemental exposure and storage conditions.

- XRF characterization showed similar general bulk compositions and several moderate to strong correlations between anticipated oxides, notably CaO to MgO and SO3, for both standard and unconventional ashes.

- Fineness testing established strong correlations between fineness measurements of SSA, d50, and 45-µm sieve retention from Blaine, laser diffraction, and the sieve test, indicating that one could be implemented to estimate the others.

Reactivity Results

R3 and modified R3 Method

The reactivity of the coal ashes that were characterized was measured in addition to calcined clay (CL), ground granulated blast furnace slag (FS), silica fume (SF), limestone (LS), basaltic fines (BT), and quartz (Q). Powder composition and fineness were determined using XRF and laser diffraction, respectively, as described in the characterization study. The inert fines have similar particle sizes to the reactive ashes.

Table 22 shows the results for all ashes; the results are summarized in Table 23. Figure 9 shows R3 data for two Class F ashes (A and F), two Class C ashes (C and D), and two inert fillers (LS and BT)

Table 23. Results of R3 (7-day) and MR3 (10-day) reactivity tests summary, shown as average ± standard deviation.

| Ash Type | R3 Heat (J/g SCM) | R3 Bound Water (g/100 g SCM) | MR3 Heat (J/g SCM) | MR3 Bound Water (g/100 g SCM) |

|---|---|---|---|---|

| Standard | 286.5 ± 91.7 | 10.3 ± 4.3 | 290.4 ± 22.3 | 21.0 ± 2.9 |

| Unconventional | 285.4 ± 91.2 | 9.0 ± 3.9 | 299.1 ± 45.1 | 19.1 ± 3.1 |

| Filler | 27.0 ± 4.4 | 1.8 ± 0.7 | 28.5 ± 14.0 | 5.1 ± 2.1 |

| Class F | 252.6 ± 72.2 | 8.2 ± 3.2 | 300.8 ± 40.6 | 19.3 ± 3.0 |

| Class C | 359.1 ± 71.7 | 14.1 ± 3.3 | 286.1 ± 34.1 | 22.1 ± 3.6 |

to provide an illustration of reactivity (heat release) curves. Corresponding modified R3 data are shown in Figure 10 for these materials. Some data are missing due to measurement error.

Both tests show significantly greater heat release for the coal ashes than for the inert fillers. However, the heat release is test method- and coal ash class-dependent. In the R3 test, the heat release of Class C ashes is much greater than of Class F ashes through the experiment duration. While this is initially true for the modified R3 test, in this case, the Class F ashes eventually catch up with Class C toward the end of the test. There was no obvious difference between standard and unconventional ashes using either test. As an example, in the R3 test, the coarse ashes showed the lowest heat release, but the highest heat release was also from an unconventional ash. However, similarly high and low values of heat release were also seen in standard ashes. Thus, consistent with results from the characterization, some unconventional ashes may show outlier behavior,

but overall, ash type appears a better predictor of performance. Low fineness (coarse particles), however, generally does seem to reduce heat release.

Heat release values for the ashes, classified using standard vs. unconventional and Class F vs. Class C, are shown in Figures 11, 12, 13, and 14. Inert LS and BT showed heat release < 50 J/g SCM in both tests. This is in line with typical heat release thresholds for inert materials, ranging from 50 to 100 J/g SCM (Li et al. 2018, Y. Wang, Ramanathan, et al. 2022a). Both R3 and modified R3 tests were able to differentiate inert materials from reactive materials using these thresholds. All coal ashes were reactive and generated heat release > 100 J/g SCM, suggesting they could be used in concrete. In the R3 test, coal ashes showed heat release 150–420 J/g SCM, whereas the modified R3 test was 200–350 J/g SCM. The more reactive calcined clay (CL), furnace slag (FS), and SF showed heat release 500–600 J/g SCM in both tests. In the R3 test, heat release for Class C ashes, about 350 J/g SCM, was considerably higher than Class F ashes, about 250 J/g SCM. In the modified R3 test, there was no difference in the ultimate heat release between Class C and Class F ashes, with heat release around 290 J/g SCM. While the modified R3 test did not show a consistent difference in the heat release of Class C and Class F ashes at 10 days, it did at 1 day.

Both standard and unconventional ashes showed on average a heat release around 290 J/g SCM, irrespective of test type, suggesting no significant difference between them in terms of reactivity.

The distinction between reactive and inert materials was even more evident in the modified R3 test, and the heat release curves of materials excluding Class F coal ashes plateaued at the end of 240 hours (10 days) (see Figure 10). The curves for siliceous materials, including Class F coal ashes, did not plateau at 7 days in the R3 (Figure 9).

All unconventional ashes were reactive, and both standard and unconventional ashes showed a broad range of reactivity. Whether the ashes were Class C or Class F had a much more pronounced effect on their reactivity than whether they were standard or unconventional. This is not to say that conventional or unconventional did not make a difference. Indeed, close inspection of the reactivity curves suggested that coarse ashes (L, S), high SO3 ash (G), and the CFB ash (C) showed somewhat different reactivity than other tested materials. Overall, the relationship between fineness and reactivity was complex, but ashes showing the lowest fineness (most coarse) generally showed the lowest reactivity. Nevertheless, because many factors affect reactivity, standard coal ashes, which

are not low-fineness, could have similar reactivity to low-fineness unconventional coal ash (as an example, F vs. L).

Reactivity was best explained by chemical composition. The R3 test has additional sulfates and carbonates that react with calcium-bearing and alumina-bearing phases, forming sulfoaluminate and carboaluminate phases. This becomes important in the Class C ashes, which tend to have more of these phases and subsequently more of an associated reaction. Therefore, the R3 test shows much greater heat release for Class C than for Class F. The modified R3 test does not have additional sulfates and carbonates and no or limited sulfoaluminate and carboaluminate phase formation. The heat release is higher initially for Class C in the modified R3 test as the calcium-bearing phases react faster, but the Class F ashes catch up due to the slower but sustained reactivity of the aluminosilicate glass they contain. The initially-large-but-reducing-over-time differences in reactivity between Class C and Class F seen in the modified R3 test but not the R3 test are strikingly similar to strength gain behavior of these ashes when used in concrete, over a different timeframe.

The results support the assertion that Class F ashes show slow reactivity and could have a large potential for heat release after the 7 days in the R3 test. The complex reactivity behavior is controlled by the interplay between additional reactions and temperature, which have different effects for Class C and Class F ashes. Kinetic corrections or longer-term testing of reactivity could be useful to better understand the longer-term reactivity behavior. Because temperature affects reaction kinetics only, sulfates and carbonates that cause additional reactions could always dominate the temperature effect if testing were carried out for a longer period.

Calcium hydroxide consumption did not strongly depend on the choice of test. The systematic differences observed in the heat release were not seen in the calcium hydroxide consumption values, possibly because additional reactions with sulfates and carbonates responsible for generating greater heat release did not consume large amounts of calcium hydroxide. The higher heat release of Class F ashes and SF in the modified R3 test did not translate to higher calcium hydroxide consumption values, possibly due to varying reaction stoichiometries. As expected, for both testing schemes, the Class F fly ashes showed higher calcium hydroxide consumption than Class C fly ashes.

Bound water trends across the two tests were highly consistent with heat release trends, as shown in Figure 15. The modified R3 test shows a weaker heat-to-bound water correlation than the R3 test, with some outliers. The best fit line in this case did not pass through the origin, and small amounts

of bound water, 2–4 g/100 g SCM, showed zero heat release. Because the bound water test was done using a TGA, not a furnace, the values cannot be compared directly with those from the standard (expressed by mass of dry paste). However, as with other literature, a strong correlation between heat release and bound water was seen. The linear correlations between heat release and calcium hydroxide consumption, when removing slag, for both tests were somewhat weaker than the correlations shown in Figure 15. The three measurements are to a certain extent interchangeable since heat release, bound water, and calcium hydroxide consumption are all driven by the same reaction processes.

From this testing, the following approximate thresholds are suggested, which work for both tests for most materials: heat release 100 J/g SCM, or calcium hydroxide consumption 30 g/100 g SCM, or bound water 5 g/100 g SCM. The research team’s results from the R3 and modified R3 tests are in line with literature. Specifically, a heat release of between 50 and 100 J/g SCM and the equivalent bound water values should in most cases differentiate inert and reactive materials.

There was a strong linear correlation between the 3-day and 7-day/10-day heat release in the R3 and modified R3 tests. The 3-day heat release was 71% of the ultimate heat release for both tests, implying that the test duration could be reduced to 3 days for both tests for all materials except slow-reacting siliceous materials. Heat release, bound water, and calcium hydroxide consumption from the R3 test generally correlated with the modified R3 values over a range of materials, with exceptions as discussed.

Reactivity findings:

- Both R3 and modified R3 reactivity tests could differentiate reactive coal ashes from inert materials at a heat release threshold of approximately 100 J/g SCM.

- Both R3 and modified R3 tests showed that all standard and unconventional ashes were reactive and showed no perceivable differences in heat release.

- Low-fineness (coarse) ash, high-SO3 ash, and the CFB ash showed somewhat different reactivity than other tested materials. Specifically, the low-fineness (coarse) ashes generally showed lower reactivity.

- Both R3 and modified R3 tests showed that reactivity of the ashes was influenced by classes, i.e., Class C or Class F, more than by sources, although heat release was also shown to vary between the two tests.

- Common features include the notion of slow but sustained reaction kinetics of heat release for Class F ashes, and vice versa for Class C ashes, which manifested at early ages when Class C ashes generally generated higher heat release.

- Bound water trends across R3 and modified R3 tests were highly consistent with the heat release patterns.

- Calcium hydroxide consumption values were comparable between the R3 and modified R3 test results on the ashes.

- Correlations between heat release, calcium hydroxide consumption, and bound water for both R3 and modified R3 were also established to varying correlation coefficients.

- Results from the two reactivity tests showed that the proposed approximate thresholds to differentiate reactive materials from inert materials may be expressed as 100 J/g SCM for heat release, 30 g/100 g SCM for CH consumption, and 5 g/100 g SCM for bound water.

Paste Results

Calorimetry Results

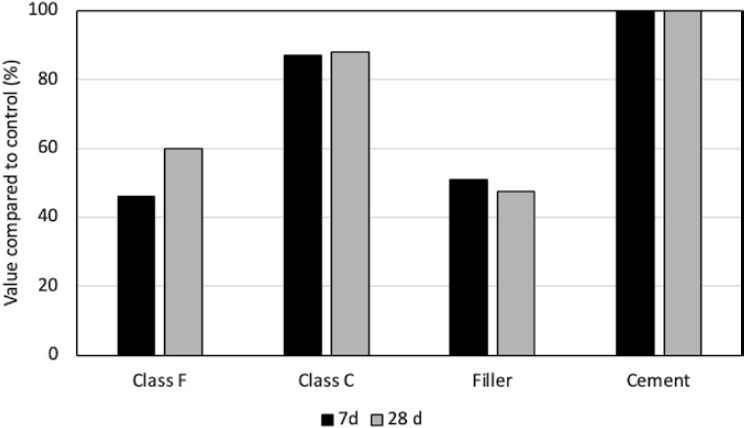

Results from paste measurements were similar to those from powder characterization and reactivity. That is, whether ashes were Class C or Class F had a major impact on several properties, on average. Whether ashes were standard or unconventional did not have a strong effect on the properties, on average, although ashes with high LOI, high sulfate, and low fineness (coarse particles) exhibited properties different from other coal ashes. Table 24 summarizes the average value of various properties, expressed as a percentage of the control for Class F ashes, Class C ashes, and fillers.

All coal ashes reduced the peak heat flow to between 67% and 82% of the control, averaging 74% (see Figure 16). The coal ashes had slightly lower peak heat flow values than inert fillers, but no differences were found between Class C and Class F ashes. The 74% value is close to the 30% reduction predicted from pure dilution, though filler effect and hydration retardation can also influence the peak heat flow. As SO3 increased, the peak heat flow increased for Class C ashes, but not for Class F ashes, likely due to the presence of different forms of SO3. The time to peak heat flow values ranged from 82% to 162% of the control, averaging 117%. Most coal ashes retarded hydration when considering the time to peak heat flow, while inert fillers accelerated hydration. Class C ashes had on average longer time to peak than Class F ashes and the time to peak reduced linearly as ash SiO2 increased. The off-specification high-sulfate ash (G) had the most significant retarding effect.

Coal ashes reduced the 7-day heat release to 74–97% of the control, averaging 82%. The values are higher than the 70% expected from pure dilution due to filler effect, but not significantly due to

Table 24. Average value (%) of various properties compared to control for Class F coal ashes, Class C coal ashes, and fillers.

| Property | Class F | Class C | Filler | Cement |

|---|---|---|---|---|

| Peak heat flow | 73 | 75 | 77 | 100 |

| Time to peak heat flow | 109 | 133 | 85 | 100 |

| 7d Heat release | 79 | 91 | 81 | 100 |

| 7d Strength | 61 | 83 | 52 | 100 |

| 91d Strength | 83 | 85 | 59 | 100 |

| 7d Bulk resistivity | 81 | 83 | 86 | 100 |

| 91d Bulk resistivity | 286 | 154 | 85 | 100 |

| 7d Calcium hydroxide | 76 | 72 | 81 | 100 |

| 91d Calcium hydroxide | 64 | 65 | 82 | 100 |

low coal ash degree of reaction. Class C ashes averaged 91% of the control, whereas Class F ashes averaged 79% of control (see Figure 17). Heat release also increased linearly with CaO content, although there was obvious scattering (see Figure 18). The lowest heat release was observed in the low-fineness (coarse) off-specification Class F ash (L), which is unsurprising. None of the tested ashes showed a strong negative effect on cement hydration, and there was not an obvious worsening of performance with unconventional coal ashes.

Bulk Resistivity Results

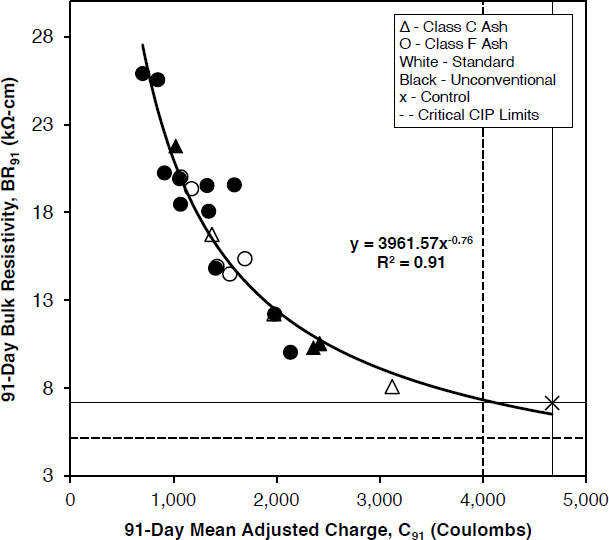

At 7 days, bulk resistivity reduced to average values of 81%, 84%, and 86% of the control for Class F ashes, Class C ashes, and inert fillers, respectively (see Figure 19). This suggested low degree of reaction of the coal ashes at 7-day age. Corresponding bulk resistivity values at 91 days are 286%,

Figure 18. Moderate-strong correlations between CaO content and 7-day heat release (darker circles) and CaO content and 7-day strength (lighter rhombuses).

154% and 85% of the control, and the ashes, especially Class F ashes, increased greatly in bulk resistivity from 7 to 91 days. As shown at 91 days, significant differences were found in bulk resistivity between Class F ash, Class C ash, and inert fillers, with the tested ashes showing significant increases in bulk resistivity values. The increased resistivity is due to greater amounts of hydrates, denser microstructure, and greater alkali binding. There was not a good correlation between bulk resistivity and coal ash SiO2/CaO content, or whether the ash was unconventional or not. Bulk resistivity appears to be a promising method for distinguishing inert and reactive materials, as discussed in the “Modifications of SAI and Development of BRI” section.

At 7 days, coal ashes also reduced paste compressive strength to a range of 48–92% of the control. Class C ashes showed higher paste strength than Class F ashes at 7 days, consistent with the heat release results. As shown in Figure 18, 7-day strength also increased linearly with CaO content with moderate correlations and highlighted the higher degree of reaction of Class C ashes at this age. Class F ashes and inert fillers had similar 7-day strengths, showing that the use of SAI testing at 7 days could be problematic (see Figure 20). At 91 days, Class F and Class C ashes had similar strength, significantly higher than with inert fillers. From 7 to 91 days, Class F ashes showed 64% strength increase; other materials were < 35%, due to the slow but sustained reaction of the Class F ashes, as reflected in the modified R3 test results (Y. Wang, Ramanathan, et al. 2022a). Even at

91 days, coal ashes reduced strength compared to the control. While paste strength testing has a number of limitations, all coal ashes increased strength compared to inert materials, especially at later ages, showing the potential use of these ashes in concrete.

At 7 days, the four ashes with the lowest strength (48–55%) were P, S, B, and Q. At 91 days, only one ash (Q) had a strength of less than 75% of the control. While P was an in-specification ash, the rest were harvested and beneficiated, and/or had high LOI or low fineness (coarse particles). Therefore, in this case, at 7 days it appears that at least some unconventional ashes reduced strength. At 91 days most of the ashes showed acceptable strength, but the high LOI seemed to have a persistent effect in reducing the strength.

Calcium Hydroxide Results

All materials reduced calcium hydroxide content at 7-day age due to dilution and low degree of reaction, with average values of 81% for inert fillers, 76% for Class F ashes, and 72% for Class C ashes (Figure 21). At 91 days, corresponding values were 82%, 64%, and 65%. All ashes reduced calcium hydroxide content on the order of > 30%, showing ash reactivity compared to filler materials. The limited differences between ash types suggest that the greater pozzolanicity of Class F ashes may be overcome by the greater degree of reaction of Class C ashes. While unconventional ashes did not show major changes in the calcium hydroxide content, the lowest contents were observed for C, the unconventional CFB ash.

Among the unconventional coal ashes, only four showed properties that could be considered significant outliers. These included the CFB ash, the off-specification high-SO3 ash, the low-fineness (coarse) ash, and the high-LOI ash. While several off-specification ashes did show differences in properties compared to unconventional ashes, as a general rule, unconventional ashes did not result in paste properties substantially different from standard ashes. While these results suggest such ashes should be specified, durability testing is needed to determine the usage of these ashes in concrete.

The 7-day strength of the pastes showed a moderate correlation with the 1-day heat release in the R3 and modified R3 tests. At 91 days, the relatively similar strength of the coal ashes is in line with similar 10-day heat release from the modified R3 test but not the dissimilar values in the R3 test. The calcium hydroxide content in the 91-day pastes had a moderate negative correlation with the calcium hydroxide consumption in the R3 and modified R3 tests, which is promising as the calcium hydroxide content is related to various measures of durability. There was a positive exponential correlation between the 91-day paste bulk resistivity and the calcium hydroxide consumption in the modified R3 test, but not in the R3 test—important because the bulk resistivity is also a durability and quality control indicator.

Paste findings:

- Standard and unconventional ashes did not appear to have detrimental effects on cement hydration and strength development, producing pastes with similar later-age properties.

- Greater reactivity and better contribution to paste strength were observed in ashes than in filler materials, especially at 91-day age. However, strengths were still reduced in most ashes compared to the control mixture.

- CaO contents of the ashes influenced 7-day paste strength, 7-day heat release, and time to peak heat flow in established positive linear correlations.

- All standard and unconventional ashes showed substantial increases in bulk resistivity with age compared to inert fillers. These results implied that greater alkali binding, higher formations of hydration products, and more microstructure development occurred in the coal ash pastes.

- Overall, early- and later-age paste properties, including strength and BR, were effectively linked to heat release and calcium hydroxide consumption in the R3 and modified R3 tests, showing promising indicators of concrete durability.

- While unconventional ashes generally resulted in promising properties, low fineness (coarse particles), high SO3, and high LOI resulted in poor performance, at least for some properties.

Modifications of SAI and Development of BRI

This section discusses modifications to improve the SAI test by increasing the percentage of coal ash replacement to 30% or 50%, maintaining a constant w/cm, and curing at elevated temperatures as described in the “Reactivity and Paste Testing Methods” section. The BRI was also computed for these ashes.

At 30% replacement, 23°C, and 7 days, there were not significant differences in strength between the coal ashes and inert fillers (see Figure 22). The Class F coal ashes and the fillers both averaged

68% of the strength of the control due to the slow reactivity of the Class F ashes. At 28 days, the strength of the Class C ashes was 84% of the control, the strength of the Class F ashes was 80% of the control, and the strength of the inert fillers was 63% of the control. However, one coal ash showed an SAI of 74% and one inert filler showed a similar SAI of 73%. Combined with the high standard deviations and errors typically around 10%, these results highlight potential issues of the SAI test when using 7-day values.

At 50% replacement, 23°C, and 7 days, no distinction between Class F ashes and inert fillers was observed, with values clustered at 45% for the three tested materials (see Figure 23). Values were 46% for the Class F ashes, 87% for the Class C ash, and 51% for the inert fillers. At 28 days, all ashes had strengths > 50%, while inert materials had strength < 50%, with values of 60% for the Class F coal ashes, 88% for the Class C coal ash, and 48% for the inert fillers. However, the difference in strength between the weakest ash and strongest filler was < 10%, suggesting that differentiation of coal ashes and fillers using this test variant is possible but challenging.

At 30% replacement and 50°C curing, 7-day strengths were well differentiated between the ashes and inert fillers, with values being 105% for the Class F ashes, 110% for the Class C ash, and 64% for the inert fillers (Figure 24). Values at 28 days were 104%, 131%, and 74%, respectively. The weakest ash and the strongest filler showed a 16% difference at 7 days and a 25% difference at 28 days.

Results were similar for the 50% replacement level and 50°C curing (Figure 25). The 7-day strength values were 78% for the Class F ashes, 126% for the Class C ash, and 56% for the inert fillers. Values at 28 days were 91%, 101%, and 49%, respectively. The weakest ash and the strongest filler showed a 14% difference at 7 days and a 19% difference at 28 days.

These findings suggest that increasing the curing temperature is a promising modification to the current SAI test to better differentiate ashes and inert fillers, and may also be promising for natural pozzolans.

At 30% replacement, 23°C, and 7 days, the BRI values expressed as a percentage of the portland cement control did not show significant differences, clustering on average around 85% (see Figure 26). The values were 85% for the Class F ashes, 85% for the Class C ash, and 84% for the inert fillers. However, at 28 days the differences were substantial, with the values being 135% for the

Figure 24. SAI (%) of coal ashes, fillers, and control at 30% replacement and 50°C.

Class F ashes, 117% for the Class C ash, and 83% for the inert fillers. The difference in value between the worst coal ash and best inert filler was about 34%, significantly larger than the typical error bars of less than 10%. This difference is also greater than the maximum differences seen with the SAI, suggesting the high selectivity of later-age BR measurements toward identifying reactive materials.

Results were somewhat worse for the 50% replacement level and 23°C curing (see Figure 27). The 7-day BRI values were 72% for the Class F ashes, 58% for the Class C ash, and 71% for the inert fillers. Values at 28 days were 142%, 81%, and 74%, respectively. At 7 days, fillers showed better results than the Class C ash. At 28 days, the worst coal ash and the best inert filler showed less than 5% difference, so this testing scheme would not be effective.

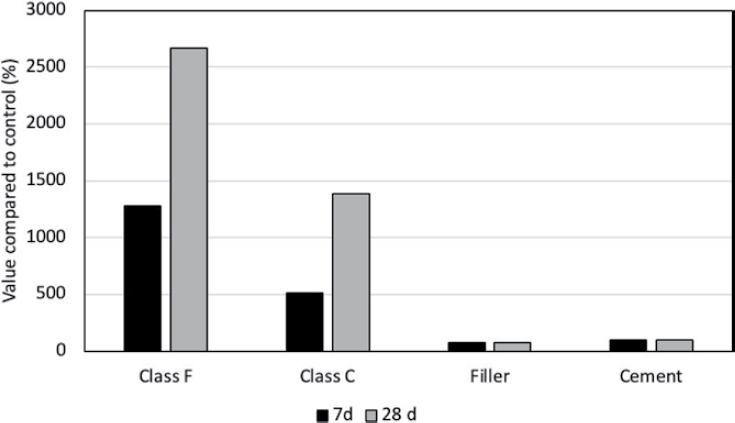

Results at 50°C curing, 30% replacement, and 7 days show a massive effect of the high-temperature curing in increasing the BRI for reactive materials (see Figure 28). The 7-day BRI

Figure 25. SAI (%) of coal ashes, fillers, and control at 50% replacement and 50°C.

Figure 26. BRI (%) of coal ashes, fillers, and control at 30% replacement and 23°C.

values were 394% for the Class F ashes, 221% for the Class C ash, and 81% for the inert fillers. Results at 28 days showed even greater differences for reactive and inert materials—1,013% for the Class F ashes, 364% for the Class C ash, and 93% for the inert fillers. Increasing temperature increases the reactivity of coal ashes, which is reflected in massive increases in their BRI. No significant effect is seen for inert fillers. The differences between the worst coal ash and best inert filler with the 50°C curing regime ranged from 100% to 1,400%, showing significant and easy distinction between the ashes and inert fillers.

Results at 50°C curing and 50% replacement are similar to those at 30% replacement at either age (see Figure 29). The 7-day BRI values were 1,279% for the Class F ashes, 515% for the Class C ash, and 78% for the inert fillers. Results at 28 days were 2,669% for the Class F ashes, 1,386% for the Class C ash, and 76% for the inert fillers. Significant and easy distinction was achieved between the ashes and inert fillers.

Figure 27. BRI (%) of coal ashes, fillers, and control at 50% replacement and 23°C.

Figure 28. BRI (%) of coal ashes, fillers, and control at 30% replacement and 50°C.

When observing the SAI and BRI data, it is apparent that from 7 to 28 days, SAI trends are inconsistent. That is, SAI for ashes increases on occasion, but not consistently. Likewise, for fillers SAI sometimes increases with age, but not always. Given that ashes react over time and fillers do not, the SAI test shows poor sensitivity to pozzolanic and hydraulic reactions. On the other hand, in every scenario tested, the BRI shows large increases from 7 to 28 days for ashes that are not seen for the fillers. These differences are magnified at high temperatures as seen in Figure 28 and Figure 29, again confirming the sensitivity of BRI to reactions.

In general, BRI increases were greater for Class F ashes due to their temperature sensitivity. Changes in BRI are driven by the rate of the coal ash reaction, pore solution pH, and pore connectivity. A BRI of 100% could be used to differentiate inert and reactive materials at 7 and/or 28 days. Based on these results, a scheme of increasing the curing temperature and measuring the BR is a promising alternative to SAI to better differentiate between coal ashes and inert fillers.

Figure 29. BRI (%) of coal ashes, fillers, and control at 50% replacement and 50°C.

This alternative may be promising for natural pozzolans as well. Using early-age BRI values at 1 and 3 days should also be considered in future testing.

BR and strength are inherently different measurements. Class C ashes show the best strength behavior, but Class F ashes show the greatest BR, at least at the tested ages. BR is far more sensitive to temperature than strength when comparing the differences in the numbers highlighted.

Heat release curves for all materials were remarkably similar at 23°C curing and 30% replacement due to the low degree of reactions at 7 days. This finding provides confirmation that the 7-day SAI does not measure reactivity and cannot be used to differentiate coal ashes from inert fillers. At 50% replacement, one coal ash showed higher heat release compared to the other four materials. At 50°C curing, coal ash pastes showed greater heat release than inert filler pastes. At both replacements, the Class C ash showed the highest heat release, followed by the Class F ashes, and then the inert materials. Heat release results are broadly in line with the SAI results and a positive correlation was found between 7-day SAI and heat.

At 7 days under 23°C curing, there was no significant difference in calcium hydroxide content for the coal ashes and filler materials at either replacement level. At 28 days, coal ash pastes showed reduced calcium hydroxide content, whereas the inert filler pastes showed increased calcium hydroxide content. In addition, at 28 days, calcium hydroxide content in coal ash pastes was significantly lower than the inert filler pastes. At 50°C curing, due to reaction acceleration, the coal ashes showed significantly lower calcium hydroxide content than inert fillers at both 7 and 28 days. Also, both coal ashes and inert fillers reduced calcium hydroxide from 7 to 28 days. This was anticipated for the coal ashes due to pozzolanic reaction kinetics consuming calcium hydroxide, but it is unclear why this is so for the inert fillers.

The bulk resistivity-calcium hydroxide consumption relationship appeared to be exponential/bilinear, with a threshold value beyond which the BR increased drastically. Although the amount of data is limited, it suggests the possibility of pore depercolation driving the increase in BR values. Further testing, including robustness, round-robin testing, and testing using more materials, should be considered for standardization of this test. However, a draft specification of the BRI method has been provided to AASHTO as Appendix 3.

SAI modification and BRI findings:

- Limited differences between coal ashes and fillers were found at 30% replacement and 23°C.

- Hydration and calcium hydroxide content measurements confirmed that there were limited differences between Class F ashes and inert fillers at 7 days.

- Increasing the replacement and especially the curing temperature to 50°C using SAI resulted in greater differentiation of 7- and 28-day SAI values between the coal ashes and filler materials.

- BR generally showed better differentiation of reactive coal ashes and inert materials.

- Accelerated curing at 50°C with both 30% and 50% replacement levels significantly increased BRI values for the coal ashes but not the inert fillers.

- The BRI test, especially at 50°C, is a promising modification that should be further explored.

- A draft specification of the BRI method has been provided to AASHTO as Appendix 3.

Mortar Testing Results

This section summarizes the results of mortar tests used to determine the strength contribution of the investigated ashes. These tests include (1) the standard compressive strength test with flow-adjusted SAI, (2) the KHI test using inert filler materials, and (3) the TSE using a higher cementitious content. MSAI results are in Appendix 5, which has been provided to AASHTO.

Strength Activity Index

Most of the coal ashes met the acceptable maximum water requirement to obtain a mortar flow within ±5% of the control flow. Only unconventional coal ashes C, S, and U showed water demands greater than the 105% water requirement limit. Water requirements for all tested coal ashes are shown in Figure 30. Most of the tested coal ashes have workability comparable to the control. For the tested coal ashes, particle fineness did not appear to play a significant role in water requirement.

Mortar SAI values from 7 to 91 days for the tested ashes are shown in Figures 31 and 32. Table 25 is provided for clarity of the SAI data. The 56-day data were interpolated from the measured 28- and 91-day data. Under the standard SAI test, most tested ashes generally showed a reduction in compressive strength compared to the control mixture at all ages. Exceptions include standard coal ash E (marginal SiO2 +Al2O3 +Fe2O3, elevated SO3) and unconventional ash J (cyclone collector ash) generating higher 7- and 91-day mortar strengths than the control, attributed to a combination of high CaO content and fineness of these ashes. Conversely, the lowest mortar strengths were observed for unconventional ashes L, M, and S, most notably due to their off-specification very coarse particle sizes. Increases in mortar strengths were generally observed for the tested ashes from 7 to 91 days. Class C ashes on average generated mortar strengths approximately 11% higher than Class F ashes at 7 days, illustrating the influence of CaO content to early-age strength development, as was also evident in paste studies. Similar to the cement paste data, by 91-day age, the contribution of CaO content diminished as mortar strengths between Class C and Class F ashes converged to comparable values. Higher increases in mortar strength compared to the control for the tested ashes, especially Class F ashes, suggested ongoing pozzolanic reaction over

Figure 32. Compressive strength and SAI (with 75% and 80% limits and 56-day interpolated strength).

Table 25. SAI of all ashes relative to the control.

| Mortar sample | SAI 7-day (% of control) | SAI 28-day (% of control) | SAI 56-day (% of control) | SAI 91-day (% of control) |

|---|---|---|---|---|

| Control | 100 | 100 | 100 | 100 |

| Standard Ashes | ||||

| A | 68 | 77 | 78 | 78 |

| D | 82 | 87 | 94 | 98 |

| E | 124 | 91 | 112 | 129 |

| F | 72 | 82 | 95 | 105 |

| H | 81 | 100 | 101 | 103 |

| I | 100 | 98 | 99 | 99 |

| P | 86 | 96 | 110 | 120 |

| Q | 79 | 84 | 92 | 98 |

| Unconventional Ashes | ||||

| B | 77 | 86 | 91 | 94 |

| K | 100 | 96 | 98 | 99 |

| M | 71 | 69 | 78 | 90 |

| N | 79 | 102 | 99 | 97 |

| O | 79 | 89 | 96 | 100 |

| R | 82 | 95 | 97 | 99 |

| S | 68 | 62 | 69 | 78 |

| C | 78 | 86 | 89 | 91 |

| G | 79 | 85 | 97 | 104 |

| J | 106 | 87 | 108 | 128 |

| L | 70 | 79 | 80 | 82 |

| T | 77 | 92 | 89 | 88 |

| U | 75 | 89 | 93 | 96 |

| V | 84 | 97 | 96 | 96 |

the 91-day period. This trend was consistent with several investigations involving coal ashes (Deschner et al. 2012, Jun-Yuan et al. 1984, Kondraivendhan and Bhattacharjee 2015, Narmluk and Nawa 2011, Sumer 2012).

Mortar strengths expressed as a percentage of the control strength on average generate SAI values greater than the 75% SAI limit for pozzolanic SCMs. Unconventional ashes L, M, and S, characterized by coarse particle sizes, generated 7- and 28-day SAI values below the 75% limit. This finding is broadly consistent with low reactivity and poor paste performance observed for some of the coarse coal ashes. At 56 days, with interpolated strengths expressed as SAIs, two of the off-specification fineness unconventional ashes M and S still had SAI values less than 75%, while the remaining off-specification fineness unconventional ash L passed the 75% SAI limit. By 91 days, all tested ashes showed significantly higher SAI values than the 75% limit. This confirms findings from reactivity testing that all ashes were indeed reactive and behaved differently to inert fillers.

Table 26 shows ashes that failed the different criteria of the SAI, including the standard 75% SAI limit at 7, 28, or 56 days. Only unconventional ash S, beneficiated by high heat treatment and with off-specification fineness (coarse particles), failed to meet the 75% limit at all tested ages. A proposed 80% SAI limit was also used to evaluate the performance of the ashes. Approximately 59% of all tested ashes and 71% of all unconventional ashes failed to pass the proposed 80% SAI

Table 26. Failure of ashes using different limits for SAI.

| SAI | Failed Ashes | |

| Limits | 75% | 80% |

| 7-day SAI | A, F, M, S, L, U | O, Q, G, N, C, B, T, U, F, M, L, A, S |

| 28-day SAI | M, S | L, A, M, S |

| 56-day SAI | S | M, A, S |

| 91-day SAI | None | A, S |

| 7-day and 28-day SAI | A, F, M, S, L, U | O, Q, G, N, C, B, T, U, F, M, L, A, S |

| 7-day or 28-day SAI | M, S | L, M, A, S |

| 7-day, 28-day, or 56-day SAI | S | M, A, S |

limit at 7 days. By 28 days, approximately 81% of all tested ashes passed the 80% SAI limit. The 80% SAI limit restricted the use of three unconventional ashes with off-specification fineness (L, M, and S) and a standard ash with low reactivity (A). At 56 days using interpolated strengths expressed as SAIs, the two off-specification-fineness ashes M and S and standard ash A still retained values below the 80% limit, while the remaining off-specification-fineness ash L barely passed the 80% SAI limit. The proposed 80% SAI limit was more conservative than the 75% SAI limit in restricting lower-reactivity ashes M, L, and A, as well as high-water-demand ash S.

Concerns of inert fillers passing the 75% SAI limit or false positives are often cited in the literature (Sutter et al. 2013, Suraneni et al. 2021), but none of the coal ashes tested here were found to be inert. As shown later in the Concrete Testing Results section, coal ashes M, L, and A all demonstrated adequate strength gain (although lower than the control) and very high BR compared to the control at later ages, indicating significant reaction. Ash S, on the other hand, had comparatively lower concrete strength and BR, but was still reactive. For this reason, requiring an 80% limit would likely restrict the use of viable ashes, especially slower-strength-gaining ashes, and is therefore not proposed as a change to the AASHTO M 295 standard.

MSAI results have been provided to AASHTO as Appendix 5. The use of MSAI with constant w/cm was found to be overly restrictive by failing certain reactive coal ashes.

Keil Hydraulic Index

The KHI results are shown in Figure 33 using nonconstant water (SAI) samples. On average, all inert materials (limestone, basalt, and quartz) showed little contribution to mortar strength at all ages when compared to the investigated ashes. There were several exceptions at various ages when a coal ash appeared to show lower strength contributions or smaller KHI values than the inert fillers, including negative KHI values for ashes S, L, and M at 7 days using inert quartz, ash M at 28 days using basalt and quartz fillers, and ash S at 28 days using all three inert filler materials. Standard high-LOI ash F and standard ash A also showed comparable or lower strength contributions than inert quartz at 7 days by generating very low to negative KHI values, respectively. M, S, and L were unconventional ashes that were characterized by off-specification fineness or very coarse particle sizes that may have reduced their reactivity and hindered their strength contribution at the ages of 7 and 28 days. Thus, KHIs using each of the inert fillers were able to catch these behaviors, implying that for these ashes most of the early-age strength gains were likely indicative of slower and lower pozzolanic reactivity. Similar behaviors were observed in the Reactivity Results, Paste Results, and Concrete Testing Results sections of this report where two of these ashes (S and L) were shown to generally generate lower strengths. KHI using quartz also successfully identified standard ashes F and A as lower pozzolanic ashes in the early age of 7 days, which accords with the strength results shown in the Strength Activity Index section of this report. Also, coal ash A was shown to have lower reactivity and to generate one of the lowest concrete strengths from 28 to 91 days.

One interesting feature of the KHI test was that it clearly showed the inertness of the filler materials over time, especially at 28 and 91 days, when their KHI values were significantly less than those of the coal ashes: 51–72% lower at 28 days and 79–121% lower at 91 days. This finding is similar to the BRI, which shows no significant increase in inert filler properties over time. Inert fillers were also clearly differentiated from the hydraulic behaviors of the cement control at both 28- and 91-day ages, generating KHI values approximately 89% to 110% less than the control. These findings on the assessment of the contribution of strength using KHI appeared to circumvent the issue of false positives in classifying inert fillers as pozzolanic SCMs, a finding consistent with Sutter et al. (2013).

The results also showed KHI values increasing with age when the coal ashes were used as the test mixtures. Among the inert fillers, it was generally shown in the KHI results that quartz generated the highest contribution to strength, while limestone generated the lowest contribution to strength.

This is somewhat unexpected, since secondary reactions with limestone are known to occur, and do not happen in quartz. Since these materials were considered inert or nonpozzolanic or at least of limited reactivity, such contributions or perceived contributions to strength likely stemmed from filler effects due to particle sizes and particle packings. Closer inspections of the data also revealed that by 91 days of testing, KHI values for the coal ashes ranged from approximately 90% to 110% compared to the 100% control datum, suggesting strength contributions of all ashes were at worst comparable to the control and at best exceeding it. When comparing by source, it was shown that 28- and 91-day KHIs of standard ashes exceeded those of unconventional ashes by approximately 15% and 20%, respectively.

Individually, coal ashes S (unconventional, beneficiated by heat treatment), A (standard), and L (unconventional) also generated the lowest 91-day KHIs across all inert fillers used. The highest 91-day KHIs were measured for coal ashes E (standard) and J (unconventional, cyclone collector ash). It should be noted that S, A, and L were also among the ashes that generated some of the lowest later-age mortar and concrete strengths while ashes E and J yielded some of the highest mortar strengths, as discussed in the Strength Activity Index section. Interestingly, ash J (Class F) generated the highest concrete strengths from 28 to 180 days, whereas ash E (Class C) generated some of the lowest concrete strengths and BRs from 28 to 180 days, as discussed in the Concrete Testing Results section, indicating that early-age KHI testing might not predict later-age behavior for certain high-calcium coal ashes.

Overall, a trend of increasing KHI values with curing ages for all the investigated coal ashes was found, implying ongoing pozzolanic reactivity or increasing contributions to strength development. This test also allowed for better differentiation of strength contribution between the filler effect of inert materials and pozzolanic reactivity of the ashes, which may provide an alternative solution to the issue of false positives of inert fillers passing as pozzolanic SCMs. However, in this investigation, the effect of water reduction remained unclear—especially in the SAI regime—and there was a drawback regarding the variabilities measured for compressive strengths. Further refinements of the KHI are recommended, although results shown in this investigation suggested that their use may be more viable than the traditional SAI tests alone and more economical than certain direct reactivity tests.

Total Efficiency Test

The results of the TE tests are shown in Figure 34. The test results indicated that filler materials did not contribute much to strength development as demonstrated by the various negative values attained for the CE, WRE, and overall TSE. Higher efficiencies (TSE, CE, and WRE) were observed for ashes A, D, and R in comparison to the control at both 7 and 28 days. By 28 days, ash R had the highest TSE, which is likely related to its higher SAI strength. Furthermore, R showed a significant increase in CE from 7 to 28 days, indicating that it was more chemically reactive than ashes A and D. Yet this finding is not supported by R3 testing where D had the highest reactivity. Ash A had the highest WRE, indicating that it had the most significant contribution to strength due to water reduction, which may be a result of its lower water requirement. Ashes A and R also exhibited negative CE values, which would indicate that their CEs contributed a negative effect to the overall TSE. The inert fillers, especially basalt and quartz, showed significant decreases in efficiencies (including negative values) from 7 to 28 days.

These results were tested for repeatability two additional times. Unfortunately, the measured efficiencies for the same tested ashes were up to 575% different between trials, with TSE and CE values fluctuating the most. Some of the efficiency values even fluctuated between positive and negative from trial to trial. This caused concern regarding repeatability of the test and uncertainties in interpretation of the results. These inconsistencies prompted discontinuation of the TE test. Although the ability to differentiate between strength contributions from chemical reactions and water reduction could be useful, the results of this test were deemed less meaningful relative to other aspects of reactivity tests, including R3 to directly assess reactivity, SAI to determine water requirements that can be controlled in concrete by admixtures, and KHI to directly compare coal ash performance to inert fillers.

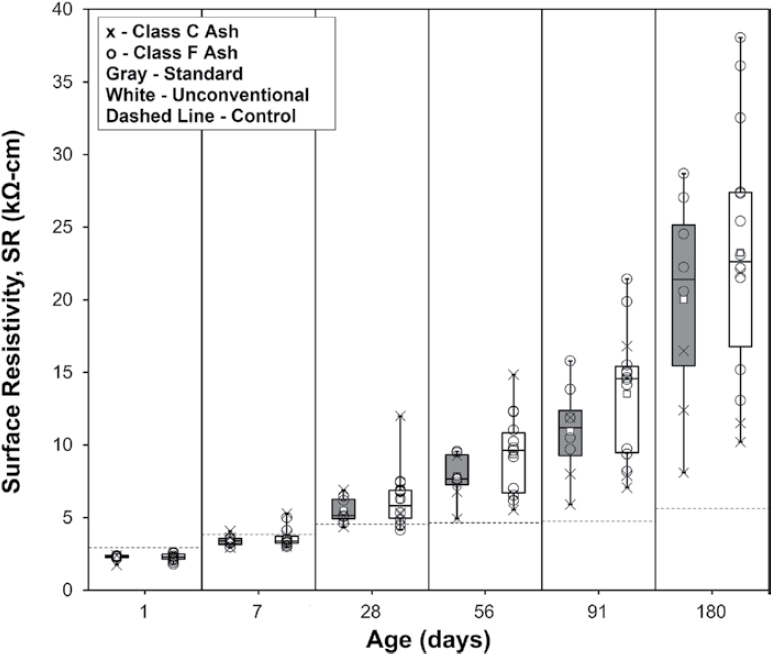

BR Measurement of SAI

Bulk resistivity measurements taken for the SAI mortar cubes are shown in Figure 35 and Table 27 to provide clarity in the measured values. Generally, there was an exponentially increasing trend in BR values from 3 to 91 days similar to that seen in paste testing. Considerable increases in BR values were shown at 56- and 91-day ages when more than 95% of all coal ashes generated BR values greater than the control mortar, indicating pozzolanic reactivity or pore refinement over time, consistent with reactivity and paste bulk resistivity results. The one unconventional ash that did not meet SAI limits, S, also showed low BR values at all ages.

Table 27. Bulk uniaxial resistivity expressed as a percentage of the control mixture (SAI scheme).

| Samples | BR3-day (% of control) | BR7-day (% of control) | BR28-day (% of control) | BR56-day (% of control) | BR91-day (% of control) |

|---|---|---|---|---|---|

| Control | 100 | 100 | 100 | 100 | 100 |

| Standard Ashes | |||||

| A | 88 | 87 | 95 | 138 | 206 |

| D | 90 | 93 | 114 | 134 | 167 |

| E | 114 | 113 | 120 | 160 | 224 |

| F | 90 | 91 | 106 | 156 | 407 |

| H | 106 | 110 | 110 | 206 | 190 |

| I | 112 | 114 | 141 | 125 | 307 |

| P | 81 | 82 | 105 | 204 | 351 |

| Q | 80 | 78 | 92 | 124 | 135 |

| Unconventional Ashes | |||||

| B | 72 | 75 | 132 | 174 | 310 |

| K | 124 | 115 | 129 | 145 | 296 |

| M | 84 | 80 | 109 | 156 | 252 |

| N | 80 | 84 | 104 | 145 | 187 |

| O | 83 | 76 | 89 | 106 | 172 |

| R | 92 | 90 | 109 | 232 | 409 |

| S | 85 | 78 | 86 | 105 | 119 |

| C | 85 | 98 | 144 | 187 | 354 |

| G | 87 | 84 | 100 | 111 | 140 |

| J | 80 | 86 | 90 | 116 | 137 |

| L | 84 | 87 | 108 | 171 | 345 |

| T | 79 | 75 | 92 | 126 | 205 |

| U | 97 | 91 | 116 | 159 | 187 |

| V | 96 | 89 | 122 | 184 | 242 |

Figure 36 shows the comparison in BR values between all ashes and the control at different ages for SAI samples. ANOVA at the 5% confidence level and Tukey-Kramer pairwise analyses were used to differentiate BR values at 91 days with respect to the control for the SAI data. For SAI at 91 days, significant differences were identified between standard and unconventional coal ashes on average, which were higher compared to the control mortar (p-values = 0.000). The differences were less pronounced at earlier ages. One potential modification to the specification could be to simultaneously measure strength and BR on the SAI samples to better differentiate reactivity of the ashes. Modifications as suggested earlier including higher percentage replacement of cement with the ash and higher curing temperatures could exaggerate the effects for better differentiation.

Mortar findings:

- Except for one unconventional coal ash with off-specification fineness (coarse particles), the remaining coal ashes generated SAI values greater than the 75% limit by 56 days, and all coal ashes generated SAI values exceeding the 75% limit by 91 days.

- A proposed 80% SAI limit and use of MSAI with constant w/cm were found to be overly restrictive by failing reactive coal ashes.

- For SAI samples, BR increased with age. By 91 days, BR values on average were significantly higher for the coal ashes compared to the control mixture. This indicates it may be a better measurement of coal ash reactivity than strength measurements alone.

- KHI detected low indices for off-specification-fineness and low-reactivity ashes and very low indices for filler materials, circumventing concerns of false-positive classification of inert fillers as reactive SCMs. It may be a good future alternative to using SAI in the AASHTO M 295 standard due to its ability to better differentiate reactivity.

- TE test results were inconsistent based on repeatability studies and inconclusive compared to other reactivity tests, so TE testing was discontinued.

Concrete Testing Results

This section summarizes the results of concrete tests for important fresh and hardened properties, electrical properties, and durability performance of the investigated ashes. Tests for fresh and hardened concrete properties include (1) the standard test for slump, density, and air content of fresh concrete and (2) the standard test for hardened concrete compressive strength. Durability tests include (1) the tests to determine electrical properties of hardened concrete using bulk uniaxial resistivity and surface resistivity measurements of hardened concrete and (2) the RCPT for performance against deleterious chloride ingress.

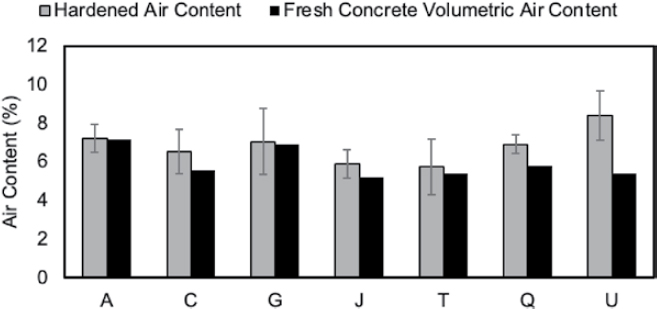

Fresh Concrete Properties

Fresh concrete properties including slump, air content, density, and 90-minute slump decrement of the tested ashes are shown in Table 28. Generally, inclusion of the ashes improved workability and increased the slump of fresh concrete compared to the cement control mixture. Numerically, 68% of the tested ashes improve concrete workability, 23% reduced workability, and 9% showed no difference in workability. This was anticipated since many of the ashes were characterized via SEMs with morphologies consisting mainly of spherical particles similar to standard ashes. Compared to the control, Class C ashes increased concrete workability measured by slump by approximately 50% in contrast to the 29% increase shown for Class F ashes. This was not anticipated since Class C ashes on average were finer than Class F, so other factors likely controlled.